In short

There is no digitalization and no digital transformation without digitization (of paper and processes).

Digital business as catalyst for change

Digital transformation – the use of technology to radically improve performance or reach of enterprises – is a hot topic for companies across the globe. Executives in all industries are using digital advances such as analytics, mobility, social media and smart embedded devices – and improving their use of traditional technologies such as ERP – to change customer relationships, internal processes, and value propositions. Other executives, seeing how fast digital technology disrupted media industries in the past decade, know they need to pay attention to changes in their industries now.

Three terms that cause confusion

Digitization

Digitization and digitalization are two conceptual terms that are closely associated and often used interchangeably in a broad range of literatures. But there's a difference.

Digitization is the automation of existing manual and paper-based processes, enabled by the digitization of information; from an analog to a digital format.

Digitalization

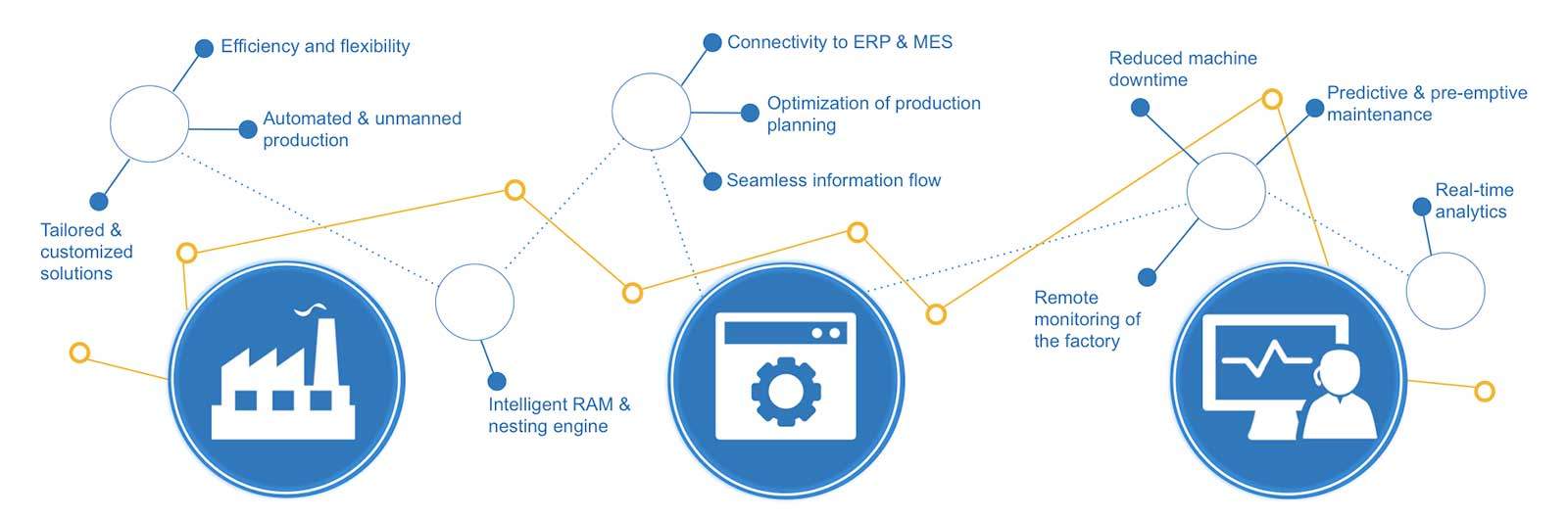

Digitalization means turning interactions, communications, business functions and business models into (more) digital ones which often boils down to a mix of digital and physical as in omnichannel customer service, integrated marketing or smart manufacturing with a mix of autonomous, semi-autonomous and manual operations.

Digital transformation

Digital transformation means the use of digital technologies and of data (digitized and natively digital) in order to create revenue, improve business, replace/transform business processes (not simply digitizing them) and create an environment for digital business, whereby digital information is at the core.

Industry 4.0

Industry 4.0 is the technological revolution that has made it possible to collect and analyse data across machines thus enabling fast, flexible and efficient processes to produce high quality goods at lower costs. At its broadest level, Industry 4.0 portends a shift not only in how companies would operate and goods would be produced, but how ecosystems—the suppliers, customers, regulatory considerations, investors, and other third-party experts and influencers—would function and interact.

Industry 4.0 has raised high expectations, but not all have been met. Nonetheless, a handful of manufacturers have discovered numerous applications for Industry 4.0 and are reaping the benefits. Implementing Industry 4.0 is a process that could take years, and more applications will develop as technologies mature further. This will build the organizational and technical muscle to tackle more ambitious projects in the future, such as the complete integration of data throughout the product life cycle.

Focus on the business impact of technology rather than implementation of new, but not business-driven systems !

An effective, well-managed digital and especially IT infrastructure is one of the most valuable business advantages an organization can secure. The right technology, implemented properly, appropriately managed and monitored, can lead to significant gains in growth and efficiency. It is essential to get sound business advice to ensure technology risks are managed.

IMG has a pragmatic approach. We create a digital agenda around 7 core initiatives – designed to speed time-to-value. It spans strategy and experimentation through to transformation leadership and performance delivery.

Our approach combines business and technology expertise and accelerates the passage from idea to implementation.